The way of displaying information has changed over the years. From times when there was only paper or blackboards, we came into the world of presenting data on monitors, smartphones, and other devices with a display.

Any form of interface that shows a state of a device and allows its user to interact with the machine is a Human Machine Interface (HMI). In other words, it is a graphical interface between a user and a machine. It is a very wide definition, that includes household appliances, office equipment, and industrial computers.

But what does the HMI mean when we think about Building Management System (BMS)?

We can narrow the definition by adding some requirements, like: an HMI is an interface between a machine or system and the operator, a kind of a dashboard, that translates complex processes and its variables into usable and practical information. This interface has to give the user possibilities to change the state of the machine or a system and monitor it.

If we go further into details for BMS an HMI will be a process control system that provides a visual representation of the controlled system in real-time.

Beginnings of the HMI

Beginnings of the HMI in Building Automation are hand-operated buttons and LEDs on an electrical cabinet. It is still a common practice since it may be a more economical solution than an HMI Panel with a display. It can be said that HMI is a push-button replacer, a possibility to gather even hundreds of buttons into one device, a possibility to centralize manual control. On the other hand, there is a possibility to decentralize control by adding Panels in many places and letting the engineer adjust the parameters when one needs to.

Moreover, an HMI can be a data handler, there is no need for extra LEDs to show the state of the device, all information can be displayed on one screen: which appliance is working, is there any alarm, and if yes – where and even why.

GUI as a part of HMI

The data handling function includes graphs with real-time data, visual representation of HVAC (Heating, Ventilation, Air Conditioning), for that there is a need of adding another definition, a GUI (Graphical User Interface). This makes HMI a user-friendly device. It doesn’t matter if the representation of the data is made by an application that comes with the panel or from a system that is displayed on a screen. It has to allow easy recognition, like using proper colors for different messages, we would use red for critical alarms. But GUI is more than just colors, it includes icons, pictures that allow for fast recognition without a need for reading instruction. Any specialist from a specific field should be able to understand the visualization.

Who can leverage from using an HMI?

As mentioned earlier an HMI can be useful in different environments, but when it comes to more complicated systems we can focus on industries that need constant monitoring, like:

- Energy

- Food and beverage

- Oil and gas

- Manufacturing

Except for manufacturing and heavy industries, there is the Building Management System, otherwise known as a building automation system (BAS). A system most commonly installed in modern buildings, like business centres, public buildings, shopping malls, museums, and many more. This kind of system is used to control and monitor the construction’s mechanical and electrical equipment, like:

- Ventilation

- Heating

- HVAC

- Electric power control

- Lighting control

- Security

- Fire alarm system

It is used not only to monitor the building and diagnose problems when they occur, but it is an important part of cost optimization, for example, reduction in energy usage. BMS helps in becoming energy-efficient by minimizing energy usage and waste.

A common use of HMI in BMS

HMI can be used in different parts of a building, from a simple wall panel that for changing the temperature in the room, to a large Industrial Panel used to monitor air handling units and in electrical cabinet doors.

There is a need for a User Interface in each BMS, usually, it is a PC with multiple screens placed in a control room. An operator is sitting in front of the computer and monitors the system. The work of this person is based on monitoring, analyzing, and modifying parameters when needed. This procedure is an essential and delicate task that guarantees the efficiency of any BMS system.

But as mentioned before, we sometimes need a more straightforward solution, an easy to access, when somebody is doing a tour around the building and wants to check if everything is ok or do some minor changes, like changing the temperature setpoint or turning on/off the pumps.

Environmental aspects

Since HMI may be used in different places around the building, we need to choose a device that will work properly. The basic environment parameters are:

- humidity

- temperature

- insolation

All these factors may shorten the life of a device that wasn’t chosen correctly or cause troubles to the user. High temperatures and humidity have a bad influence on display and electronics if the housing and electronic components are not prepared for such an environment. When it comes to insolation, it may be difficult to read information from a display if it doesn’t have high luminosity. All these will affect the price of a solution. That is why when choosing an HMI we need to take all factors under evaluation.

iSMA HMI Panels

iSMA offers 2 kinds of industrial HMI Panels:

- Industrial Panel with HDMI (iSMA-D-PD10C-B1)

- Industrial Android Panel (iSMA-D-PA7C-B1, iSMA-D-PA10C-B1, and iSMA-D-PA15C-B1)

Industrial Panel with HDMI

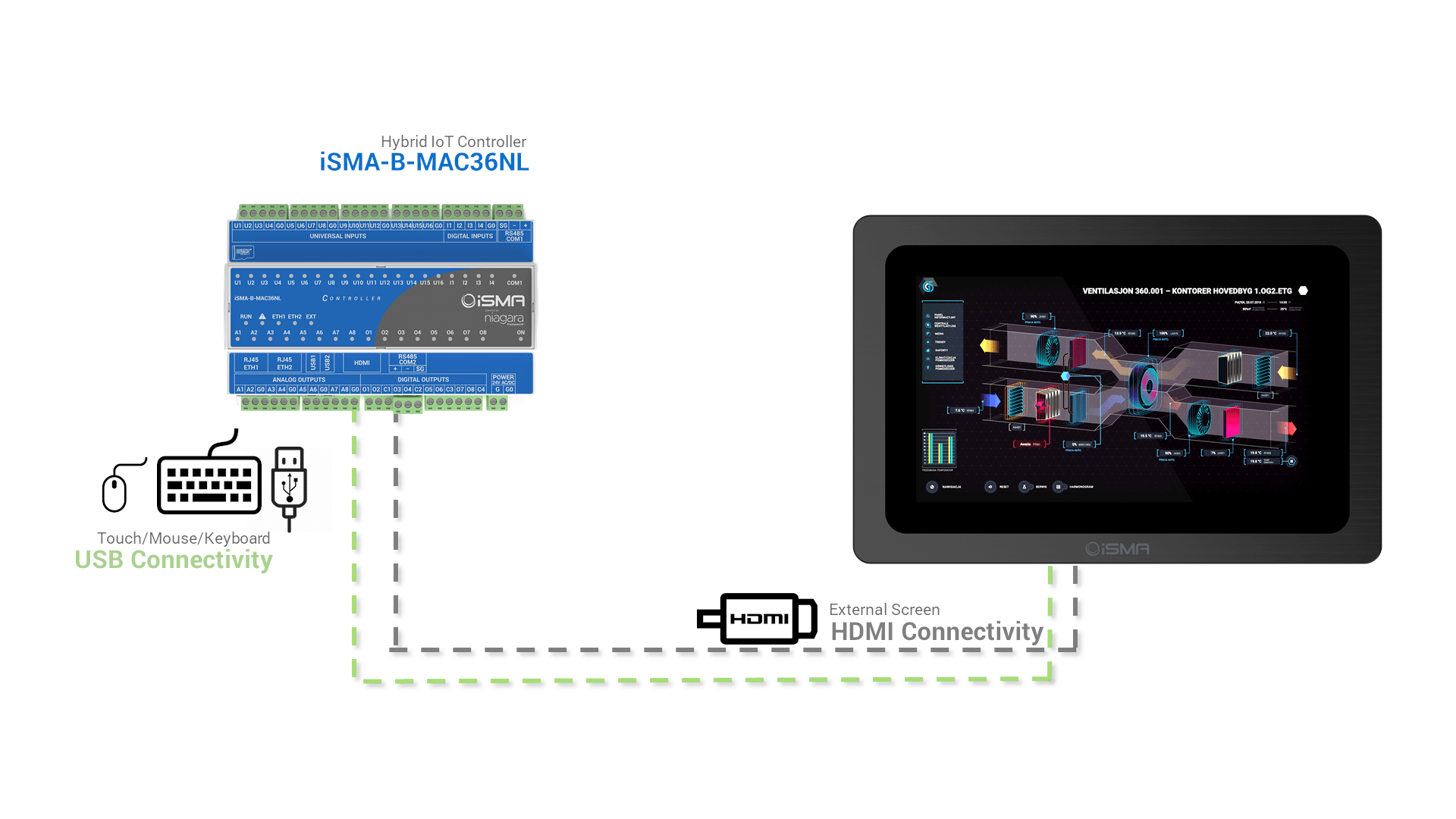

The Industrial LCD Panel with HDMI was designed to create a perfect duet with iSMA-B-MAC36NL, to display information from the BMS system. Connection of the panel is easy, the user just needs to connect the HDMI cable to the controller and the panel to send the image. The second cable RJ45-USB is used for supporting capacitive touch screen, to make touch operations possible.

The 10’ display has a high resolution, brightness, and luminance, to display sharp images. The kit includes components for rack mounting and VESA mounting. The industrial LCD panel is available with an EU, UK, or US power plug.

Industrial Android Panel

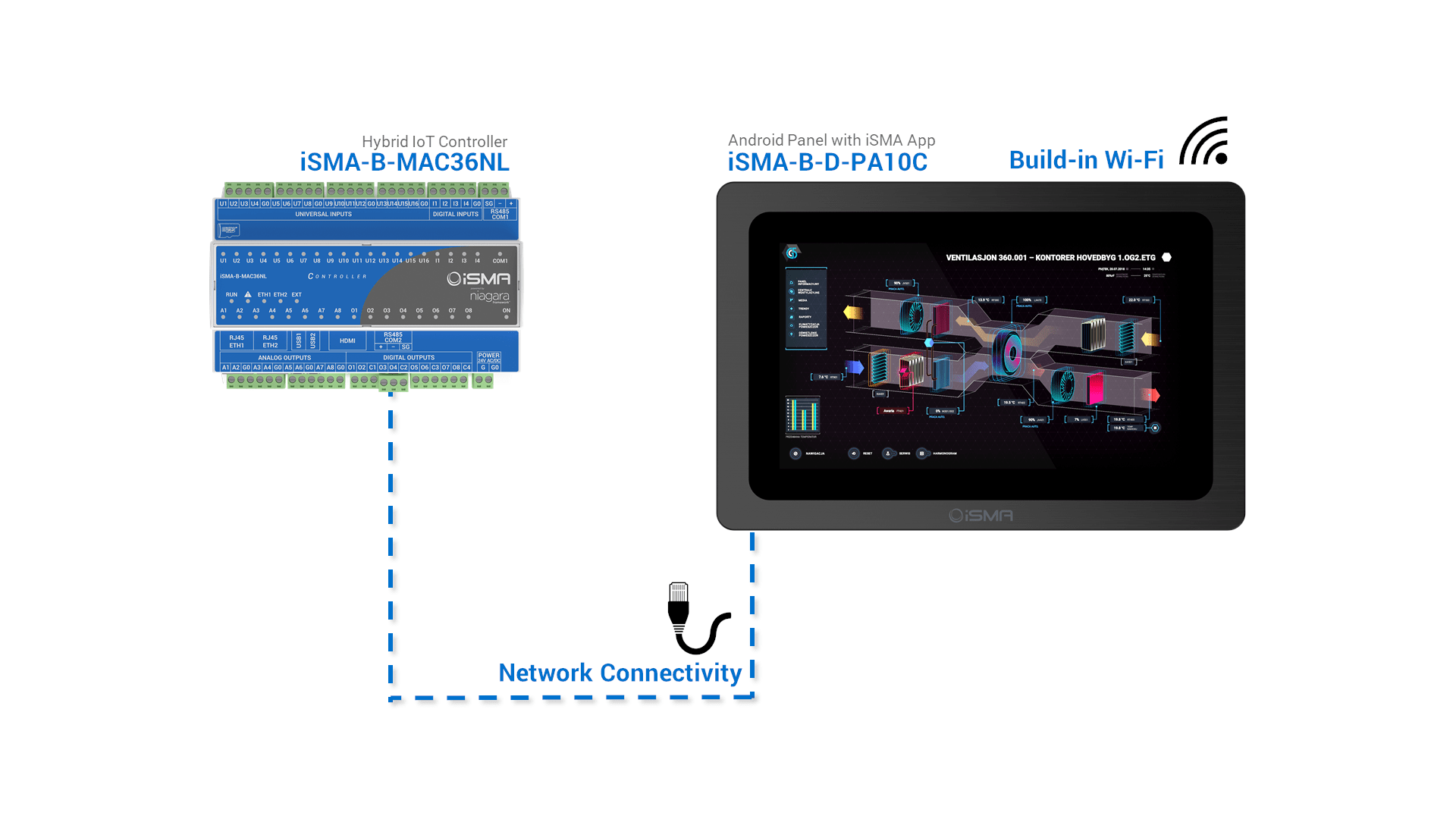

A more advanced option is to use iSMA Android Panel. iSMA has three sizes available: 7′, 10’, and 15’, all of them have high resolution, contrast, and brightness to display sharp images. IP65 for the front panel allows the use in more hush environments where water-resistant and dustproof devices may be needed. The same as the Industrial Panel with HDMI. It comes with a kit for a rack, VESA mounting and with EU, UK, or US power plug.

The product can cooperate with Niagara and non-Niagara controllers, the only limitation is that the device has to support HTML5.

As an HMI it can be used in three ways:

- Connect the Industrial PC Panel with Android to a controller using ETH cable and display graphics by a web page or iSMA Android application.

- Connect the Industrial PC Panel with Android to network and login via a web page to display graphics

- Connect Industrial PC Panel with Android to network, install iSMA Android Application, and log in to Niagara station to display graphics

What is the iSMA Android Application?

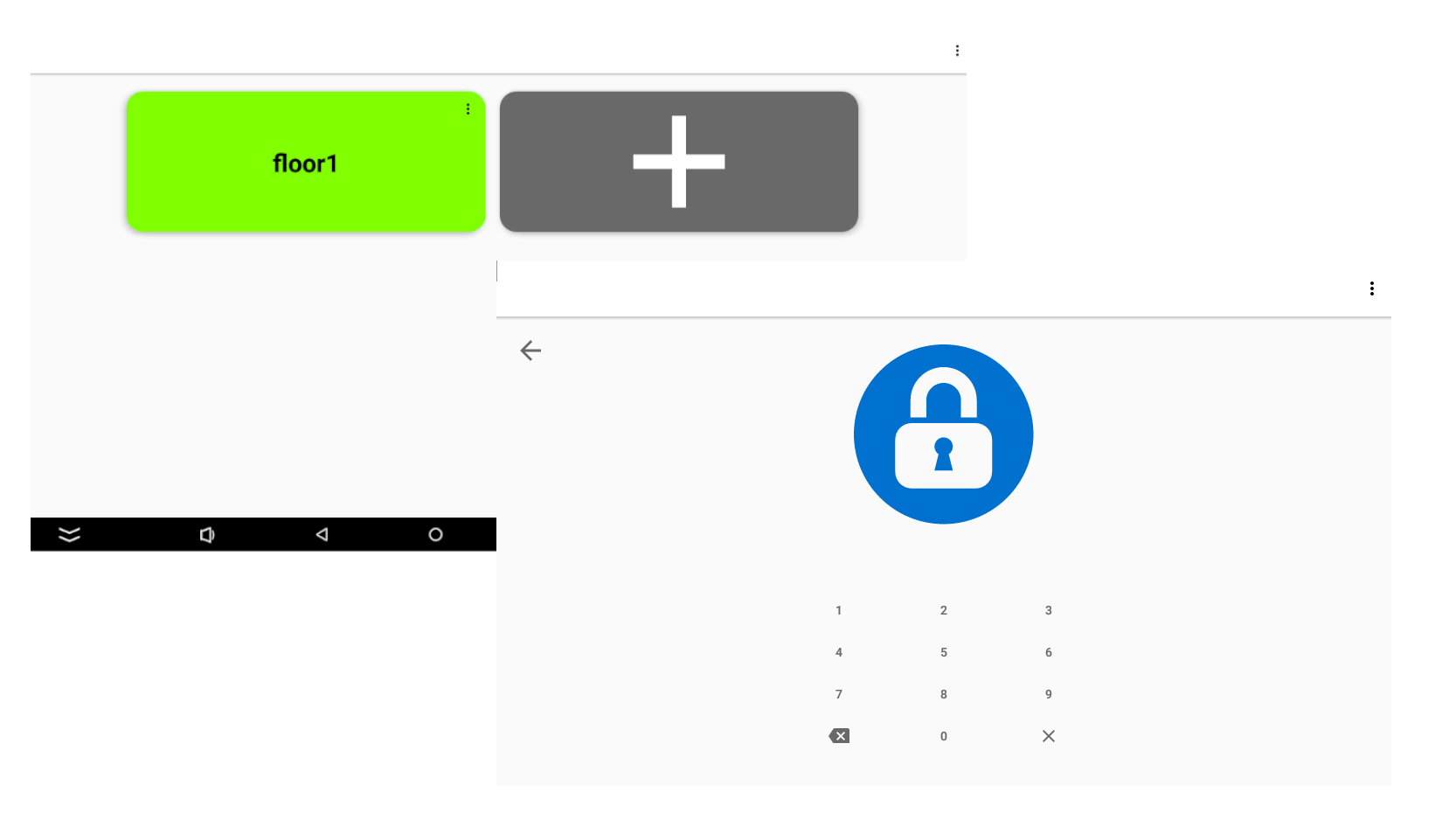

iSMA created iSMA Android Application to facilitate the use of Niagara controllers. When there are many users or stations, for example, different people should have other restricted access, there is a need for constant logging in a web browser. To do so, the user needs to remember the IP address, user ID, and password and enter them each time.

What we have done is a possibility to add multiple stations/users and save its credentials. If there is a need for safety, we added a PIN lock that can be enabled. The PIN lock works the same as on any smartphone.

Moreover, to make sure that iSMA Android Application is turned on all the time, we configured it as a home application, which means that it will turn on once iSMA Android Panel turns on. Additionally one of the added connections can have a “Home station” setting on.

Another option, that was made for making sure that no other application distracts the user, is Kiosk Mode. In this mode, the app is in full-screen mode and there is no possibility to turn on any other app or even change the settings.

To make sure that installation and configuration of many iSMA Android Panels with the application is easy, we decided that the application is preinstalled on the device, the user will decide if one wants to use it or not. There is also the possibility to export the configuration of the app from one panel and using a USB stick import it to the next one. It means that the user can add connections to one panel and duplicate the configuration on multiple devices.

With all these features, iSMA Android Panel with the application can be easy and efficient solution for displaying graphics from the BMS.

iSMA Graphics for creating GUI and visualizations

As mentioned before, a well-made GUI has to be intuitive for its user. There is a graphics library, called iSMA Graphics designed especially for iSMA-B-MAC36NL for HVAC and lighting applications. The user can find there:

- over 300 high-quality, modern, and colored 3D images representing plant items and devices,

- some of the graphical widgets are animated which enables the equipment status to be represented by different images via colors or positions,

- the library covers HVAC related equipment such as heating, cooling, air-handling, and other building control devices like lighting, metering, piping, and motion detection.

The design is elegant and dedicated to a dark background. It is a fast and convenient way to create graphics that will be understandable for any BMS specialist.

Summary

People are used to interactive displays with easy to read GUI, the same solutions are getting more and more popular in industrial environments. Some time ago engineers were used to electrical cabinets with LEDs and buttons but now they need a convenient solution that can show them more than just an on/off or alarm state. The possibility to change system parameters next to a machine allows the user to check if the machine is working properly after and make adjustments if necessary.

In the iSMA portfolio, we have all that is needed to create modern solutions that will fit many solutions.